This week, SAP gave a first sneak preview of the S/4HANA 2022 edition. We have listed all the highlights and will zoom in on the specific functionalities that are important for our focus industries: Retail, Wholesale and Production.

Supply Chain Management in SAP S/4HANA

Improved packaging/carriers and loading planning functionality

A smart new feature for Supply Chain Management has been added to the new version. This function allows you to fill packaging using unified package building, a generic layer for packaging. Until now, the automatic packaging option in Logistics General (LO), Transportation Management (TM) and Extended Warehouse Management (EWM) used different packaging functionalities based on different packaging rules. With Unified Package Building, you can use your favourite packaging functionality in any of the three components, e.g. use packaging construction not only in TM, but also in LO and EWM.

- Take advantage of new consistency checks for packaging construction restrictions and minimise the number of pallets, while taking into account restrictions such as packaging attributes, product stacking rules, customer-specific requirements and height limits.

- Maximise the use of containers/carriers by taking into account various restrictions such as dimensions, vehicle attributes, stacking rules, loading sequence, flexible split-deck.

- Create a load plan manually and increase flexibility by creating multiple load plan PDF files in batch.

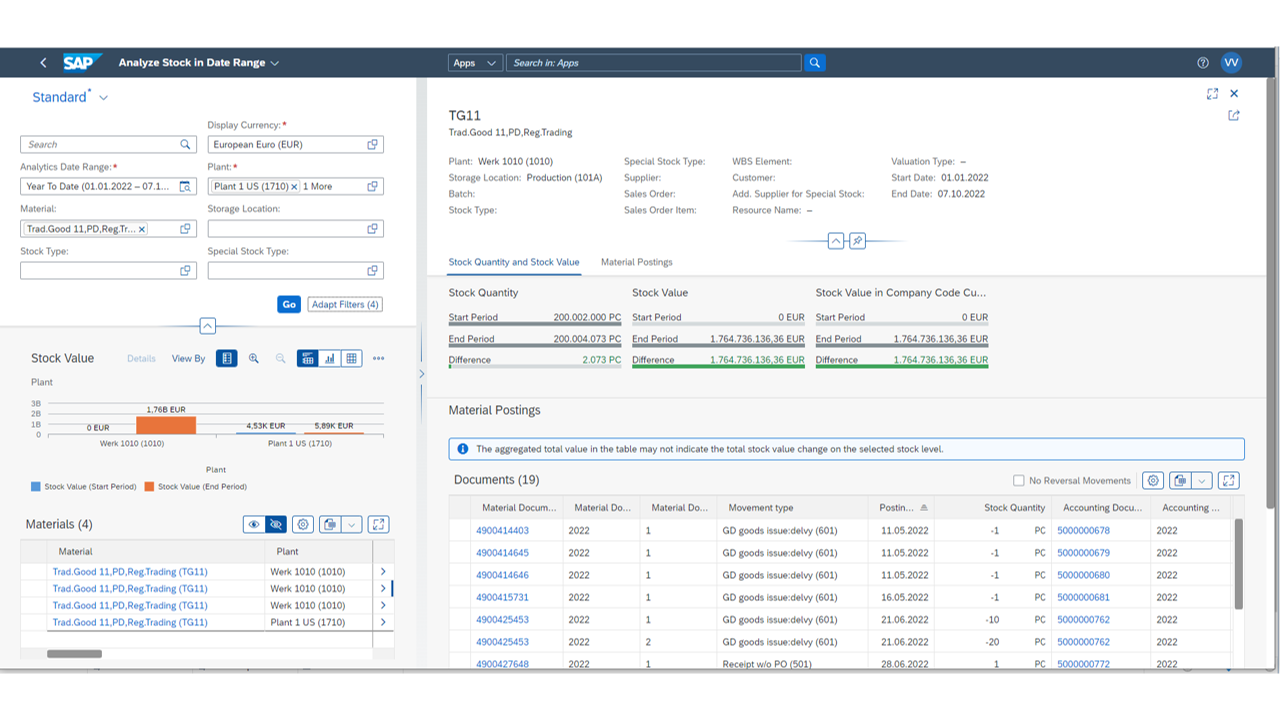

Analyse your stock within a specific time frame

‘Analyse stock in date range’ is a new analysis app that allows you to analyse and track goods movements in a single app. In particular, you can:

- Analyse and track the movements of goods of one or more materials within a specific date range

- Obtain a comprehensive analysis of all goods movements that took place within the defined date range

- Availability of all stock-identifying fields as dimensions and additional KPIs (such as absolute and relative booking differences) to deepen the analysis through aggregations and disaggregation.

Production in SAP 4/HANA 2022

Time-phased delivery days and minimum stock levels

This function allows you to use a new safety stock method: time-phased delivery days. This offers the possibility to use dynamic, time-dependent stock levels to cover material requirements, taking into account a minimum safety buffer level and a desired safety buffer level. Purchasing or production is automatically activated to make stock levels continuously available for material coverage.

Comparing bills of materials

We have made a number of improvements to the bill of materials. One of the highlights here is the new bill of materials (BOM) comparison app, which allows you to compare the following:

- The same bill of materials with different alternatives and validity dates.

- Bills of materials from different factories to understand how the production process differs in each factory.

- Different types of bills of materials (sales order BOM and material BOM) to understand how the ‘as engineered’ product structure differs from ‘as sold’.

- Bills of materials with different BOM applications.

- Version BOMs and date-effective BOMs.

The app also allows you to analyse the comparisons and gives you a detailed comparison result.

-

Procurement and Sourcing in SAP S/4HANA

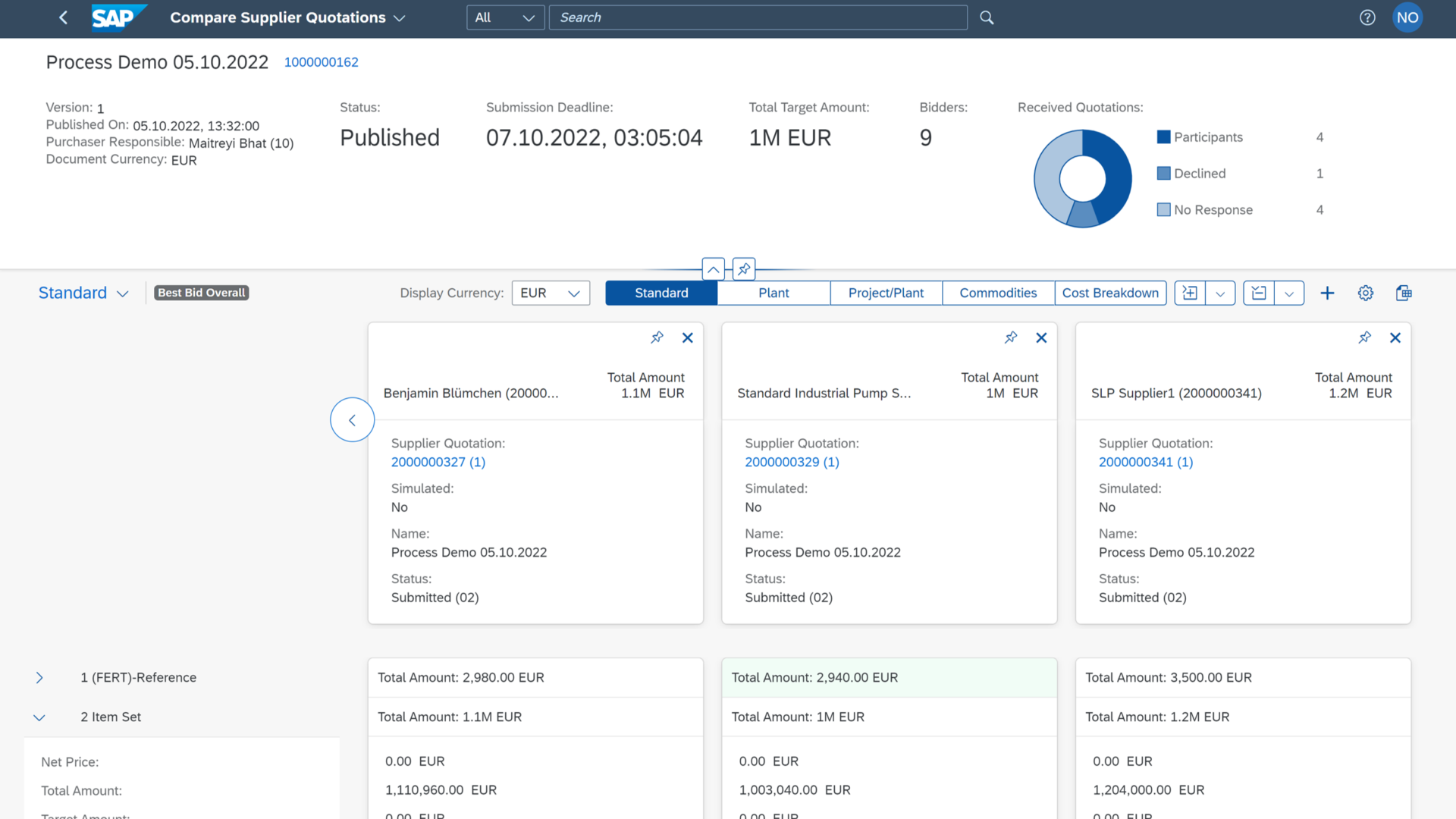

Sourcing Project: Comparison of supplier quotations, cost specification and commodities

Identifying and contracting with selected suppliers for your direct materials and services is crucial in managing the large portion of costs for both private companies and public organisations. SAP has introduced a new series of possibilities for ‘Product Sourcing’. One of the highlights is the new Manage Sourcing Projects app.

- Easily create and manage multiple cost analysis templates for the combination of company code, purchasing organisation, material group, etc.

- Collect more detailed costs linked to each item listed in the supplier quotation

- Easily compare detailed cost elements of each item with different supplier quotations